Industrial as well as domestic loads need speed variation. Some of the loads require to change the speed in steps and some of the motors require to change the speed uniformly. For instance, in the paper industry, while rolling the paper on a roller, the roller speed should decrease uniformly otherwise the paper will break.

Similarly the speed of a domestic appliance, mixie, to be changed depending upon the ingredients in the jar. Likewise, we can quote so many examples where speed control is essential.

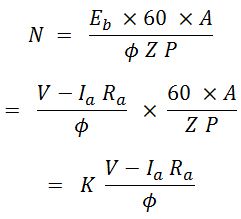

From the above discussion, it is clear that speed control is very essential. The expression for the speed of a D.C. motor is given by,

Where,

K = 60A/Z P Constant for a given motor

From the above expression, it is clear that speed can be controlled by varying- Flux, (flux control method).

- Armature circuit resistance (rheostatic method).

- Applied voltage (voltage control method).

Speed Control of DC Shunt Motor :

In a shunt connected dc motor, the speed is approximately proportional to the input voltage to the armature and inversely proportional to the current in the field winding.

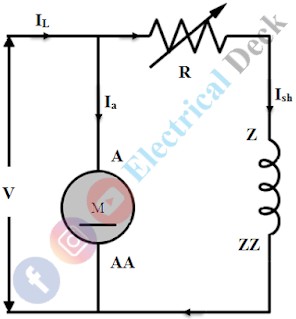

Flux Control Method :

It is seen from the above equation that N α 1/Φ. The flux of a dc motor can be changed by varying Ish with the help of a shunt field rheostat as shown. When R is increased Ish and hence α decreases. Consequently, the motor runs above the normal speed. If field resistance has decreased the speed also decreases.

Advantages :

- It is economical since very little power is wasted due to relatively small Ish.

- The speed control is independent of the load on the machine.

Disadvantages :

- Above the rated speed only can be obtained since Rsh cannot be reduced.

- If the flux is reduced too much commutation becomes poorer.

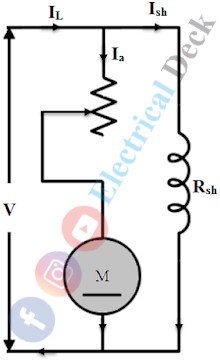

Rheostatic Control Method :

This is based on the fact that by varying the voltage across the armature, the motor speed can be changed. This is easily done by inserting a variable resistance (controller resistance) in series with the armature.

When the controller resistance is increased, the voltage drop takes place in it and the armature does not receive full supply voltage. Consequently, the back emf is less than when the armature is subjected to full voltage. Therefore armature speed reduces since N α Eb.

Advantages :

- Speed control is easy.

Disadvantages :

- Large power is wasted in controller resistance since it carries full armature current Ia.

- This method controls the speed and load currents. This double dependence makes it impossible to keep the speed sensibly constant.

- The output and efficiency of the motor are reduced.

- Only speeds below the normal speed can be obtained.

Voltage Control Method :

Multiple voltage system :

In this method, the shunt field of the motor is not disturbed and is permanently connected to a fixed voltage source. The armature is supplied from different sources through suitable switchgear. The speed varies depending upon the voltage applied. However, this system is not much used because it needs more voltage sources.