Necessity of Starting a Three-phase Induction Motor :

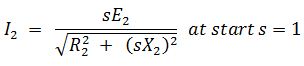

In a 3-phase Induction motor, the magnitude of rotor induced emf depends upon slip. The equation for Rotor current of induction motor is given by,

At starting, the magnitude of rotor induced emf and slip will be maximum. This emf circulates a very high current through the rotor. The induction motor acts as a transformer having short-circuited secondary at the start. Hence a rotor current is high, consequently, the stator draws a very high current of the order of 5 to 8 times full load current.

Damage to the stator winding and large voltage drop can occur when such huge currents are taken by the stator winding at starting. It may also affect the working of other equipment connected to the same line. Therefore, a starter is necessary to limit the current drawn by the motor at the start.

Starters not only limit the starting current but also provide protection to the motor against overloading and low voltage conditions.

Advantages of Using Starters for Induction Motor :

The functions of the starter are,- To start and stop the motor.

- To limit the starting (or in rush) current, when necessary.

- To permit automatic speed control when required.

- To protect the motor and other connected equipment from sustained overload, low voltage, etc conditions.

Methods of Starting a Three Phase Induction Motor :

From the expression of current, it can be seen that starting current can be limited to a safe value,- Applying a reduced voltage to the stator consequently reduces E2.

- By adding resistance in the rotor circuit at the start.

The various types of starters are,

i. Direct-on-line (D.O.L) Starter (full voltage starting) :

Usually, induction motors of small ratings (5 hp), have robust construction. The construction of such motors is made in such a way that, they can withstand high currents during starting (i.e., more than the rating of the motor).

So motors of this type can start directly by connecting across the supply terminals. For making such a direct connection a starter is needed to be called 'Direct on Line Starter', where full voltage is applied across the motor at start.

ii. Auto Transformer Starter :

In this method, an auto-transformer is used as a starter. It can be used for both star and delta connected motors, mostly used for star connected squirrel cage motors.

At starting reduced voltage is applied across the motor with the help of an auto-transformer, so that emf induced E2 can be reduced, thereby reducing the current. Once the motor gains its speed the auto-transformer is disconnected from the motor with a change-over switch.

iii. Star-delta Starter (Reduced voltage starting) :

In a star-delta starter, the starter winding of the motor is connected in star connection at the time of starting. So that full voltage with reduced current can be applied to the starter terminals. Eventually, when the motor picks up its speed (reaches its normal speed) the star-connected starter winding is then connected in delta.

A TPDT (triple pole double through switch) is used to change the connection from star to delta or vice-versa. Care should be taken while changing connection, otherwise direction of rotation of the motor can change due to changes in phase sequence. Hence this type of starter can only be used for motors running on a delta connection.

iv. Rotor Resistance Starter (Used for slip ring motors) :

Rotor resistance starter can only be used for slip ring motors where we can insert external resistance with the help of a commutator. Here a variable resistance is used to change the resistance values of the motor. The resistance is connected in series with the rotor circuit. As the motor reaches its normal speed the resistance is gradually cut off and finally removed.

We know that when the resistance of the circuit increases the current flowing in the circuit decreases. Therefore the current can be limited at starting by changing the resistance of the rotor.

The first three starters are used for both the squirrel cage and slip ring induction motor. Therefore large three-phase squirrel-cage induction motors are started with star-delta and autotransformer starters. Small motors below 5 hp ratings may however be started direct-on-line (D.O.L).