What is Hunting or Surging or Phase Swinging ?

When a synchronous motor is loaded, there exists a phase angle between rotor and field 'α'. When load increases slowly, angle 'α' also increases so that torque produced is more. So that it can maintain synchronism between the stator and rotating fields and running the load without any variation in speed.

Consider a synchronous motor whose rotor is rotating at a synchronous speed. Let, rotor be at an equilibrium position as shown in the below figure.

When this load on the motor suddenly falls then angle 'α' also changes accordingly to the new load. But in this process, the rotor overshoots, and the shaft of the motor starts oscillating from its position (swinging forward and backward like a pendulum) as shown in the below figure. These oscillations make the motor cause 'hunting' for the right position. This phenomenon is also known as phase swinging (or) surging.

If this frequency of oscillations is equal to the natural frequency then mechanical resonance is set up and the amplitude of the swing of the rotor poles relative to the poles of the rotating field becomes so great that the machine is thrown out of synchronism.

Hunting is an objectionable characteristic of synchronous motors, due to this the power drawn by the motor can vary which can change the working performance of the motor.

Causes of Hunting :

i. Driving a motor for varying load :

The main cause of the hunting or phase swinging in a synchronous motor is due to changing load conditions. Frequent variation of load on a synchronous motor can affect its speed. Also synchronous motor can withstand the changes in load condition. But, when it reaches a certain permissible value it may affect motor performance.

ii. If the frequency is pulsating :

If the nature of the supplied frequency is pulsating it may result in hunting. Due to which there will be a production of vibrations on the rotor shaft and it starts swinging. The variable frequency power supply causes the torque pulse vibrations on the rotor.

iii. Change in field current :

We know that the internal generated voltage or EMF is directly proportional to the field current. Due to variation in supply current to the field poles varies the strength of the poles. But, when this variation is more than withstand value. The motor becomes unstable and thrown out of synchronism.

iv. Faults in supply given :

Hunting in the synchronous motor is also caused when there is a fault in the supply given to the motor. This changes the normal working conditions of the motor.

Prevention of Hunting in Synchronous Motor :

Use of Damper Winding :

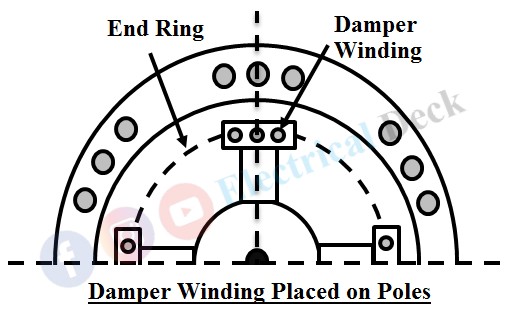

Hunting or Phase swinging in a synchronous motor is prevented by making a change in the construction of the rotor. Special bars of conductors are embedded in the field poles of the motor. The ends of these conductors are short-circuited without any electrical connection as seen in the construction of a squirrel cage rotor in a squirrel cage induction motor. This arrangement in a synchronous motor is known as ' Damper Winding '.

The damper winding is not only used for starting the synchronous motor. When there are any oscillations in the rotor as the damper winding is short-circuited. Due to the relative motion, the damper winding generates a rotating mmf that suppresses out the oscillations as shown in the below figure.

Under normal conditions i.e., when the motor runs at synchronous speed, no such currents are induced in it, and there is no effect of damper winding on the main winding. However, the damper winding cannot prevent the oscillations completely. But it can prevent the motor from running out of its synchronism.

Use of Flywheel :

A flywheel is an external arrangement connected between the motor and prime mover of that motor. Usually, a high weighted flywheel is used for this purpose. Due to its great inertia, it stabilizes the relative motion of the rotor due to oscillations, and it controls the rotation without any variation in speed.