A thermistor is a passive transducer mainly used for the measurement of temperature. It is also referred to as thermal resistance i.e., the resistance depends upon temperature. These thermistors when subjected to temperature variations, there will be a change in their resistance. Thus if we measure the change in resistance value, the applied temperature can be determined.

Thermistors have a negative temperature coefficient and also a positive temperature coefficient. But usually, negative temperature coefficients thermistors are used. The property of the negative temperature coefficient is that the resistance of the thermistor increases with a decrease in temperature and decreases with an increase in temperature.

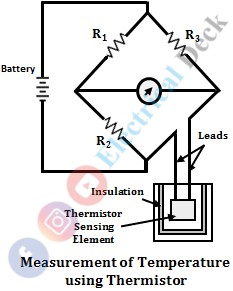

This variation in the resistance due to variation in the temperature is known by the Wheatstone bridge circuit. Since the resistance changes with respect to the change in temperature, by measuring the resistance value temperature can be determined.

Construction of Thermistor :

The thermistor consists of a metal tube, leads, and temperature sensing element. The temperature sensing element is the main part of the thermistor, which senses temperature variations enclosed in a metal tube. The sensing element is basically a thermal resistor made with sintering (pressing) mixtures of metallic oxides like copper, nickel, cobalt, iron, manganese, and uranium.

The sensing element is covered with an insulating material before enclosing it with the metal tube. Two leads are connected to the temperature sensing element and are brought out of the metal tube. The other end of the two leads is connected to one of the arms of the bridge circuit (generally Wheatstone bridge is used) which measures the resistance of the temperature sensing element.

The commercial thermistors are made in the form of beads, probes, discs, and rods in a variety of sizes as shown below. Thermistors are highly sensitive to temperature variations, which makes them suitable for precise temperature measurements. They are used for measuring temperatures ranging from -100°C to +300°C.

Types of Thermistors :

Depending upon the variation of resistance value with respect to the variation of temperature there are two types of thermistors.

- Negative temperature coefficient (NTC) thermistor

- Positive temperature coefficient (PTC) thermistor.

Negative Temperature Coefficient or NTC Thermistor :

NTC thermistors have a negative temperature coefficient there will be an inverse relationship between resistance and temperature i.e. if the temperature of the thermistor increases the resistance decreases. They are made of oxides of Mn, Ni, Co, Uranium which are milled in proper proportions with binders, pressed into the desired shape, and sintered.

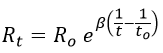

This type of thermistors are widely used for measuring temperature. The resistance temperature relation can be expressed by the following relationship,

Where,- Rt = Resistance at temperature (t) Kelvin

- Ro = Resistance at temperature (to) Kelvin

- β = A constant (usually lying between 3400 to 3900).

The curve above shows the resistance variation with the temperature of an NTC thermistor. The change is non-linear. They are available in values ranging from few ohms to megaohms.

Positive Temperature Coefficient or PTC Thermistor :

This type of thermistors has a positive temperature coefficient i.e., their resistance increases with an increase in temperature. It is shown in the below figure.

These are usually made from titanates of barium, lead, and strontium. Positive temperature coefficient thermistors are mainly used as protective elements in electric machinery for the protection of windings in transformers and motors etc.

They are used as a device to protect all kinds of electrical apparatus against overheating. If the apparatus is overheated PTC thermistor resistance raises sharply. The relay coil would be de-energized and the apparatus is disconnected from the supply.

Working of Thermistor :

Initially, a known value of current is given to the thermistor sensing element, and resistance of the thermistor sensing element is calculated. Then after the thermistor is placed in media whose temperature is to be measured.

Now when the thermistor is placed in the media whose temperature is higher than the temperature of the sensing element. It causes heat up the sensing element and the temperature of the sensing element increases.

Suppose if the thermistor sensing element has a negative temperature coefficient. The resistance of the sensing element decreases due to an increase in its temperature. Similarly, if the temperature of media decreases the temperature of the sensing element also decreases which in turn increases its resistance.

This variation in resistance of the thermistor sensing element is measured by the Wheatstone bridge. The temperature of the media is determined depending upon the resistance measured by calibration.

Calibration of Thermistor :

- At first, the thermistor is placed at a temperature of 0°C and its resistance is measured at this temperature.

- Now the leads of the thermistor are connected to any one of the arms of a balanced Wheatstone bridge.

- The bridge gets unbalanced when the thermistor is connected to it. By varying the resistance of the thermistor the bridge is again rebalanced.

- Now the thermistor is placed at a certain temperature say 50°C. This causes to change in the temperature of the thermistor and hence resistance. Hence the bridge becomes unbalanced.

- Again by changing the resistance of the thermistor, the bridge is balanced again. By this, the thermistor is calibrated to measure the temperature ranging from 0 to 50°C.

Advantages of Thermistors :

Because of the following advantages, the thermistor is an efficient temperature sensing transducer compared to the other temperature sensing transducers.