Compensation is required in thermocouples for calibrating precise and accurate measurements. The errors which are caused in the calibration of varying ambient temperature can be eliminated by compensation circuits or compensating cables.

There are different types of compensating circuits of thermocouples. Some of them are,

- Cold junction compensation

- Bridge type compensation or automatic compensation

- Bimetal element compensation.

Cold Junction Compensation :

The thermocouple is the most widely used electrical method for the measurement of temperature. The total thermo-emf generated by a thermocouple is given as,

Where,- C1 = 62.1 μV/°C

- C2 = 0.045 μV/°C (for copper-constant thermocouple)

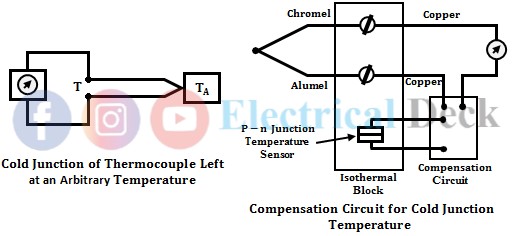

In the above equation, the thermo-emf depends on the measuring junction temperature as well as cold junction temperature. Measurement of temperature using thermocouple when cold junction left at an arbitrary temperature and compensation circuit for cold junction temperature is shown in the figure below.

In the figure above figure one junction of the thermocouple is kept at temperature T, using other junction we can measure temperature TA. The temperature TA is at a steady-state (i.e. not likely to change quickly) even though this arrangement generates different thermo-emfs.

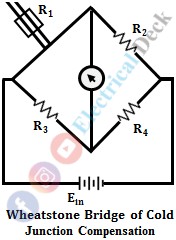

In any type of industry, it is very difficult to maintain the reference junction at an ice point. Therefore, to avoid this drawback we can use a method called bridge circuit for cold junction compensation. The Wheatstone bridge for cold junction compensation is shown below.

When the measurement circuit consists of a temperature-sensitive compensating resistor then the arrangement is used for cold junction compensation. The change in ambient temperature affects both the reference junction of a thermocouple and compensating resistor since a temperature-sensitive compensating resistor is placed near the reference junction.

As the temperature of the reference junction increases, the resistance of a temperature-sensitive compensating resistor increases, hence we find some amount of drop in the ouptut emf of the thermocouple. Therefore, the increase in the resistance value of compensating resistor results in a decrease in emf of the thermocouple.

Bridge Type Compensation :

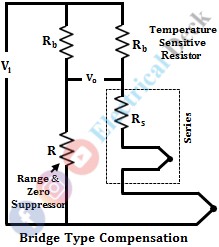

The temperature-sensitive resistor such as a thermistor is connected in series with the resistor which in turn connected in series to a thermocouple junction. This bridge should be attached very near to the reference junction. Bridge type compensation is a modified form of the former type compensation (i.e., temperature-sensitive resistor type).

The resistor R is the range and zero suppressors. A small voltage is applied in series with the standard cell. This voltage is set with the help of a temperature-sensitive resistive bridge. The changes in the ambient temperature are compensated by calibrating the variation in resistor Rs and the compensating junction.

Bimetal Type Compensation :

The ambient temperature can also be compensated by using a suitable bimetallic element. This element is connected to a spring and the spring is attached to a moving coil meter.

The whole arrangement is kept in between the two pole pieces. The change in the temperature of the reference junction or meter case causes the change in the temperature of the bimetallic element. This temperature change in the bimetallic element leads to the contraction and expansion of the spring which results in the variation of meter reading.