The electromechanical tachometers (dc and ac tachometer generators) are suited for measuring angular velocity up to 10000 rpm. For measurement of high speeds effectively, various digital methods are employed, where there is no physical contact between the tachometer and rotating shaft whose speed is to be measured.

As the speed is measured without any physical contact, the loading of the shaft is avoided. The most commonly used digital methods for measuring angular velocity or rate of rotation or angular speed are,

- Photoelectric type tachometer

- Inductive type tachometer.

Photoelectric Type Digital Tachometer :

Construction :

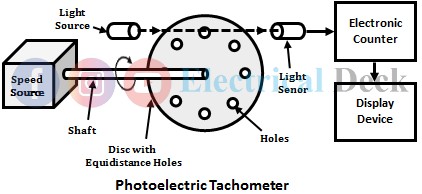

The measuring assembly of the photoelectric method consists of an opaque disc having a number of equidistant holes on its periphery, a light source, and a light sensor. The light sensor can be a photosensitive device or a phototube.

The disc is mounted on the shaft whose speed is to be measured. The light source is placed at one side of the disc and the light sensor is placed in the same line with the source at another side of the disc.

They are placed in such a way that the light passes through the holes of the disc when it rotates. The below figure shows the photoelectric tachometer for measuring angular velocity.

Working :

When the shaft rotates whose angular velocity or angular speed is to be measured, the opaque disc also rotates with the shaft. During the rotation of the disc, when the opaque portion of the disc is between the light source and photosensitive sensor, the light beam emitted by the light source doesn't reach the light sensor (i.e., photosensitive sensor). Thus there is no effect on the sensor and no output pulse will be produced by the sensor.

But, when a hole on the disc comes between the light source and sensor, light falls on the sensor and there is a pulse output signal from the sensor. The frequency of the pulses produced by the sensor is proportional to the number of holes on the disc and the speed of the disc rotation. As the number of holes is fixed, the pulse rate completely becomes the function of speed.

The output pulses produced by the sensor are measured by a digital frequency counter. The measure of pulse rate gives the speed of rotation of the disc (angular velocity) once the counter is calibrated in terms of speed (rpm).

Advantages of Photoelectric Tachometer :

- This arrangement uses simple electronic circuitry since the amplitudes of generated pulses are constant.

- The digital output can be available. Hence can be used in digital instrumentation systems.

Disadvantages of Photoelectric Tachometer :

- The lifetime of the light source is limited. It is around 50,000 hrs. Therefore, it has to be replaced frequently.

- The small gating period of digital meters leads to serious errors. To minimize the errors the operator has to control gating and also the number of pulses produced per revolution.

Inductive Type Tachometer (Tooted Rotor Variable Reluctance Tachometer) :

The inductive type digital tachometer employs a toothed rotor and a magnetic pickup. It is also called a Tooted Rotor Variable Reluctance Tachometer. The toothed rotor is mounted on the shaft whose speed is to be determined and magnetic pickup which has a coil wound on a small permanent magnet is placed near the toothed rotor so that an air gap is formed between them with a certain amount of reluctance as shown below.

The reluctance of this air gap changes when the toothed rotor rotates and thus an emf is induced in the coil of the pickup. Due to the teeth of the rotor a pulsed output is obtained.

The frequency of pulses produced is determined by the number of teeth on the rotor and the angular velocity of the rotor. Since the number of teeth is fixed, the frequency of pulses depends only on the angular velocity (i.e., the rotation speed of the rotor).

Therefore, by counting the frequency of pulses the rotational speed of the rotor can be determined. An electronic counter is employed to measure the frequency of pulses nothing but the rotational speed or angular velocity. The output pulses can be in the form of any wave shape.

Let,- T = Rotor teeth,

- P = Number of pulses per second, and

- N = Speed of rotation in rps.

Then,Number of pulses per revolution = Number of teeth = TTherefore, the speed is given by,

Advantages of Inductive Type Tachometer :

- It is very simple with rugged construction.

- It is maintenance-free.

- The calibration process is very easy and simple.

- Information from the device can be easily transmitted.

Disadvantages of Inductive Type Tachometer :

The main drawback of this tachometer is, it cannot measure small speeds because at low speeds the magnitude of induced voltage pulses may not sufficient to trigger the counter.