Induction heating is a type of electric heating in which currents induced in the material by electromagnetic action are used to heat it. It is a contactless electric heating method in which the material will be heated without making any direct contact with the supply. The operation of induction heating is based on the principle of ac transformers.

Principle of Induction Heating :

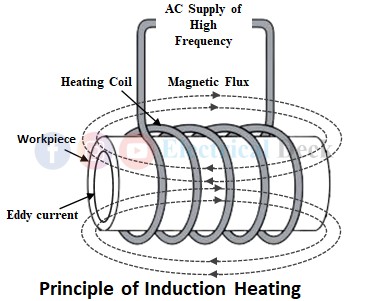

Before discussing the construction and operation of induction heating, let us see about the principle of induction heating. The principle of operation of induction heating is based on Faraday’s law of electromagnetic induction and on the concept of Joule or resistance or ohmic heating. The below figure represents the principle of induction heating.

It consists of two coils primary and secondary which act as the primary and secondary winding of a transformer. The primary is connected to an ac supply of high frequency, and the secondary is used to heat the workpiece. In the above-shown figure, the workpiece to be heated will act as the single-piece short-circuited secondary winding.

When a high-frequency alternating current is given to the primary coil, it set up an alternating magnetic field. This flux when links the workpiece, induces an emf in the workpiece resulting in the flow of eddy current through it, similar to how eddy currents are induced in the secondary winding of the transformer.

We know that according to the Joule Heating effect, thermal energy is produced in a conductor when an electric current flow through it i.e., power is dissipated in the form of heat. Thus eddy currents induced in the workpiece will develop heat in it, thereby increasing the temperature of the workpiece.

Due to the low resistivity and high conductivity of metals, they are well suited for induction heating compared to non-metals. In the case of non-magnetic material, the heat developed will be due to eddy current loss. Whereas in the case of magnetic material, the heat developed will be due to both eddy current loss and hysteresis loss.

The various factors on which induction heating depends are,- The magnitude of primary current, since if the primary current is high the flux is high, and hence secondary current will be high, thus heat developed is high.

- The supply frequency, since hysteresis and eddy current losses, depends on frequency.

- The magnetic coupling between primary and secondary, if the distance between the primary coil and material to be heated is less the magnetic coupling in more and thus heat developed is more.

- Permeability and resistivity of the material.

Inductor Design in Induction Heating :

The following are the factors to be considered while designing inductor for an induction heating,- Since magnetic flux density due to the flow of current in a conductor is maximum near the conductor, hence closer the coil to the part to be heated, the greater will be the heating effect.

- Eddy current in the parts to be heated flow in such a way so as to produce magnetic flux just to oppose the change in the magnetic flux of the inductor coil. The contour of the coil has to be such as to produce the desired heating.

- Due to the skin effect, high-frequency current in the inductor coil usually flows through the outer portion. Thus, the inductor coil is made of copper tubing through which cooling water flows to remove the heat generated in it.

- A high concentration of heat in inaccessible zones can be achieved by single turn coils carrying heavy currents. Electronic heaters can load up to 300A. Therefore for higher output, air-core type transformers are used which are less efficient.

- Lead wires from the power supply to the inductor coil should be kept as short and together as possible to avoid reducing the power factor. Even the turns of the inductor coil should be kept close together and the air gap between the coil and workpiece should be kept minimum to prevent a low power factor.

- In the case of brazing, it is essential that the joint should be first brought to the correct temperature before the brazing alloy melts and is drawn into the joint.

The above induction heating principle is used in induction furnaces for heating various materials.

Types of Induction Furnace :

Induction furnaces are basically two types, they are,- Core type or low-frequency induction furnace, and

- Coreless type or high-frequency induction furnace.

Core Type or Low Frequency Induction Furnace :

This furnace consists of a circular hearth in the form of a trough, which contains the charge to be melted in the form of an annular ring. The iron core is large in diameter and is magnetically interlinked with an electrical winding energized by an ac source as shown below.

The furnace is therefore essentially a transformer in which the charge to be heated forms a single turn short-circuited secondary and is magnetically coupled to primary by an iron core. The charge is melted due to the heavy current induced in it. When there is no molten metal, no current will flow in the secondary. Thus to start the furnace, the molten metal is to be poured into the hearth.

The core type induction furnaces are again classified into two types, direct and indirect core type induction furnaces. In a direct core type induction furnace, the charge to be heated will form the single-turn secondary circuit as shown above. Whereas in an indirect core type induction furnace, there will be a heating element that forms secondary, the heat produced in the heating element is transmitted to the charge by radiation.

Coreless Type or High Frequency Induction Furnace :

In a core type induction furnace, there is an iron core through which primary and secondary are magnetically coupled. But in a coreless induction furnace, there is no core and thus heating of material will be due to eddy currents flowing through it as shown below.

The furnace consists of a refractory or ceramic crucible in a cylinder shape. The crucible is surrounded by a coil which acts as the primary. When this primary is connected to an ac supply, it induces an eddy current in the charge to be heated. The eddy current induced will develop heat in the charge and also an additional stirring action due to electromagnetic forces is produced in the charge.

Due to the absence of a core in this furnace, flux density in the furnace is low. Thus the supply to the primary should be of high frequency in order to compensate for low flux density, hence this furnace is also called a high-frequency induction furnace.