Construction of Variable Reluctance Stepper Motor :

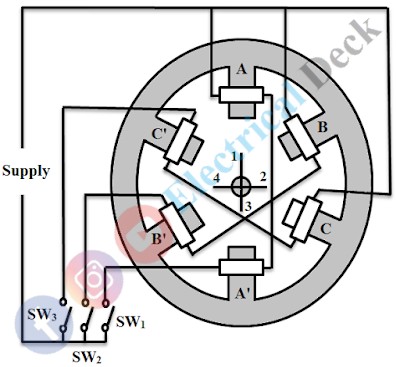

It is the most basic type of stepper motor. The stator of this motor consists of a three-phase wounded type. It has six salient poles with concentrated windings around each one of them. The rotor has 4 slots to produce the effects of 4 poles.

The two stator windings which are in the opposite direction are connected in series. These windings are then energized by three different switches as shown in the figure.

Principle of Operation :

The basic working principle of the reluctance motor is based on the various reluctance positions of the rotor. When a voltage signal is given to any one of the phases of the stator and excited, it setups a magnetic field whose axis lies along the poles.

Now the rotor tries to rotate in such a direction that it has to achieve minimum reluctance. Such a rotation means a position where the axis of the magnetic field set up by a stator will be equal to the axis passing through any two poles of the rotor.

Let us see the operation when the windings A, B, and C are connected in sequence and energized one after the other, with the help of switches SW1, SW2, and SW3.

Case - 1

When the supply is connected across the terminals of AA¹, closing the switch SW1. There exist magnetic poles between the windings AA¹. Now, due to the force of attraction of this magnetic poles rotor tries to achieve the minimum reluctance position. Therefore axis of the rotor 1 and 3 tries to get in aligning with the axis of the poles AA¹.

Case - 2

Now when the supply is connected across the windings BB¹. There is a change in the magnetic axis of the stator poles axis from BB¹. Now the rotor again tries to achieve a minimum reluctance path, thereby moving the rotor.

Here we can see that the rotor pole axis 2 and 4 are nearer to the windings BB¹. This causes a rotation of the rotor so that the axis of the rotor poles 2 and 4 get aligned with BB¹. Therefore, moving the rotor to a step movement of angle 30 degrees as shown in the below figure.

Case - 3

Similarly, when the windings CC¹ get supplied with switch SW3 and AA¹ and BB¹ are disconnected. The rotor pole axis tries to align its position with the stator pole axis. Here we get another 30° of rotation by the rotor. We totally get an angle of 60° of step motion from phases AA¹ to CC¹.

By successively exciting the three phases in the specific sequence, the motor takes 12 steps to complete one revolution. The direction of rotation of the motor depends upon the sequence of supply given to each stator phase. The torque developed by the motor, which acts on the rotor is proportional to the square of the phase current (T ∝ i2).

Important Observations :

From the above discussion, the following observations can be made,- When the sequence of supply to phases is A-B-C-A...., the movement of the rotor is in an anti-clockwise direction.

- When the sequence of supply to phases is C-B-A-C..., the movement of the rotor is in a clockwise direction.

Therefore step angle is given by,αs = 360⁰ / n pWhere- n = No. of stator phases, and

- p = No. of rotor pole/rotor teeth.

Micro Stepping :

To get a micro-step movement of the rotor. The supply to two phases AA¹ and BB¹ are given at the same time by closing the switches SW1 and SW2. Here the axis of the magnetic poles of the stator lies between the two phases. Hence the rotor tries to align with its axis, i.e., half step 15°.