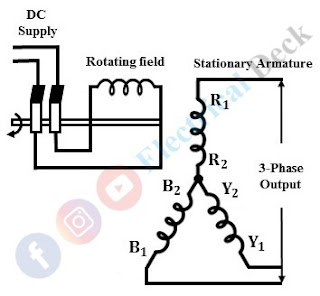

Generally, in all the electrical machines (generator or motor or alternator) we notice that armature is placed on the rotor i.e., as a rotating part, and field winding remains stationary on the stator. The below figure shows the arrangement of the stationary field and rotating armature with slip rings of a synchronous machine.

But in practice, the construction of a synchronous machine with a stationary field and rotating armature has limited applications. In almost all commercial synchronous machines, the construction is made in such a way that the armature is kept stationary and the field is a rotating part.

Advantages of Stationary Armature and Rotating Field :

The arrangement of the stationary armature and rotating field is shown below. Almost all the large synchronous machines built today have a stationary armature and rotating field structure.

The use of stationary armature and rotating field synchronous machines made a number of advantages in commercial applications.

Ease of Construction :

Usually, the alternators used at the generating stations are 11kV and 33kV, and in some industrial applications, high voltage synchronous motors are used. As the voltage rating increases the size of the motor increases. The construction of armature winding becomes more complex on the rotor as the voltage increases.

Thus when a stationary armature construction is used. It is easy for phase connections and bracing of windings to prevent any deformation being produced by the mechanical stresses set up as a result of high centrifugal forces.

Better Insulation to Armature :

The current in the armature windings increases as the rating of the machine increases. No difficulty is experienced in insulating the stationary armature winding for very high voltage (up to 30,000 V or more). Also, it is easy to insulate low voltage dc winding (field winding) placed on the rotor.

Number of Slip-rings Required :

The generation of electrical energy is at three-phase through three-phase alternators. In order to transmit three-phase generated power in the rotating armature, at least three slip-rings are required.

For large synchronous machines rated in MVA's, the transmission of power through slip-rings at high voltages (generally 11 kV) may cause some problems. Also, it is difficult to insulate slip-rings of high voltage 3-phase windings on the rotating shaft.

When the armature is kept stationary, two slip-rings are required for the supply of dc power to the rotor. Since the exciting current supplied to the field winding is at low voltages insulation of slip-rings becomes easy.

Reduced Rotor Weight :

Since the field winding is supplied through dc power weight of the rotor reduces compared to 3-phase winding placed on the rotor. Also, the insulation required to insulate field winding from the shaft is less weighted, thereby reducing the inertia of the rotor. Therefore the rotating field is comparatively light and can run at high speeds with less rated speed pick up time of the machine.

Improved Ventilation Arrangement :

It is easy to provide a cooling arrangement for stationary armature windings operating at high voltages. The output current can be collected from fixed terminals on the armature or stator to the load.