Nowadays metals are mostly used for the manufacture of the product. Almost all the products are made of metal and the process of welding is very commonly employed in the manufacture and in the repair of metal products. Welding is the only technique for joining two or more pieces of metal.

Previously joints were made using rivets or bolts in the construction of bridges, ships, etc. But these require holes in the metal to be used to make a joint which reduces the cross-sectional area (up to 10 percent) of the metal piece.

Gusset plates are also needed for the joint which increases the cost as well as the weight of the material. But in welding, both the cost as well as the material required is reduced. Thus welding has eliminated the above drawback and made the work very easy and economical.

The introduction of automotive welders, laser welders, and electron beam welders makes the welding highly accurate. These things provide a stable inherently strong and permanent joint. Welding is very advantageous for industries and factories like shipbuilding, automobile manufacturing, construction, and oil industries.

Depending upon how the heat applied is created, there are different types of welding methods they are, electric welding, thermal welding, and gas welding.

What is Electric Welding?

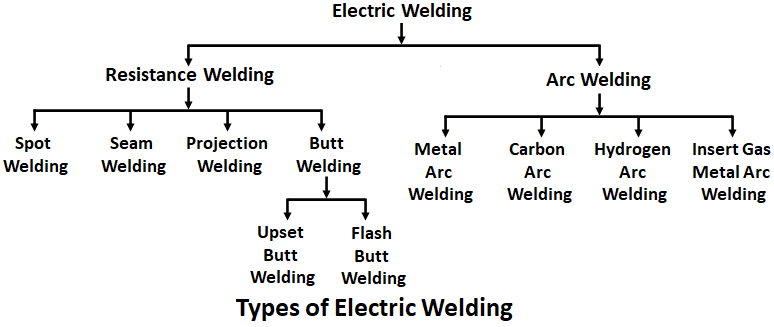

Electric welding is a process by means in which two metal pieces are joined together by the heat produced due to the flow of electric current. Due to the reliability of welded joints in comparison to rivetted or bolted joints, electric welding has been adopted in many engineering fields. There are two methods by which electric welding can be carried out. They are,

- Resistance welding,

- Arc welding.

In resistance welding, the heat produced at the joining point is due to the resistance offered to the flow of electric current. In electric arc welding, the heat developed at the point of the joint is by an arc struck between two electrodes or between an electrode and metal to be welded.