Electricity generated at all the power plants is alternating i.e., ac, in order to generate direct current i.e., dc, a commutator is used to convert the generated ac supply into dc supply. Hence, an electrical generator with a commutator fixed on the shaft is known as a DC Generator.

Normally, an electrical generator converts mechanical power into electrical power i.e., mechanical power as input and electrical power output. Almost all the generators work on the principle of electromagnetic induction. Let us see the construction of the dc generator.

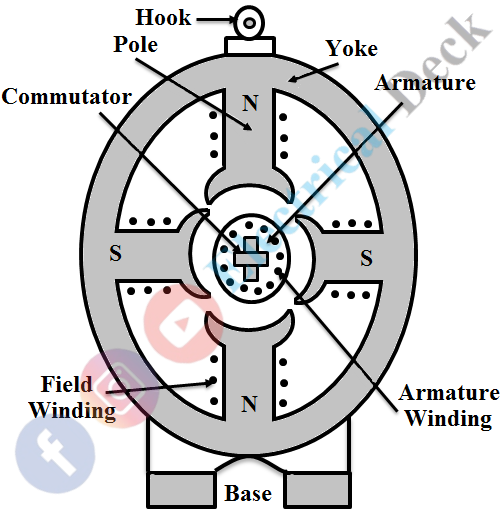

A dc generator consists of mainly two parts. They are stationary part (which doesn't rotate with the rotor) and rotating part (which rotates with the rotor).

Stationary parts of a dc generator are,- Yoke or magnetic frame.

- Pole cores and pole shoes.

- Field windings.

- Brushes and Brush Holders.

- End Covers

Rotating parts of a dc generator are,- Armature core.

- Armature Winding.

- Commutator.

- Shaft.

Yoke or Magnetic Frame :

The frame or yoke is an outer part of a dc generator that covers all the parts of a generator without any exposure. It is made up of high mechanical strength to withstand any damage caused externally to the motor. It also protects other parts inside the motor.

It is made of cast iron for small machines and cast steel or rolled steel is employed in large machines. It also prevents external dust from entering the motor. The pole core and pole shoes of field winding are fixed to the yoke and act as a return path of magnetic flux for field winding.

Pole Cores and Pole Shoes :

The core material where field winding is placed is known as pole core. The pole shoes are used to support the pole core and the shoes are fixed to the yoke with the means of bolts. Most machines use laminated steel material made up of pole cores.

It holds the field winding and helps to establishes the magnetic poles. It provides a low reluctance path for magnetic flux generated by the field winding. As the field winding doesn't rotate with the rotor. Hence, pole core and pole shoes are stationary parts.

Field Winding :

Winding is one of the essential parts of any generator cause we cannot generate the required flux without a winding. Because we cannot generate the required emf in a generator by using permanent magnets. The field winding is nothing but a copper wire wound around a pole core.

Aluminum is also used for winding. This field winding generates magnetic flux to establish magnetic poles when the supply is connected across them. Two opposite poles are connected in different polarities in order to generate two different magnetic poles.

Brushes and Brush Holders :

Brushes and brush holders are the stationary part of the generator. The brush holders are used to hold the brushes. While being used to collect current from the commutator. The main function of the brush is to supply the amount of current generated to the load circuit.

High-grade carbon is used for brushes so that sparking can be prevented while collecting current from the commutator. The terminals are connected to the edges of the brushes and brought out of the machine.

Armature Core :

The core which holds the armature winding is known as the armature core. The armature core is fixed to the shaft of the machine and rotates with the machine. It is cylindrical in shape.

The armature core is made up of very reluctance material i.e., silicon steel which is laminated by thin shits, and these sheets are separated by means of varnish in order to reduce eddy current losses. Holes are provided on the core to flows air through it for sufficient cooling of winding. The core is divided into different slots and the winding is placed over the slots.

Armature Winding :

Similarly, as the field winding there will be one more winding placed over the armature core is known as armature winding. But, armature winding is a rotating part of the machine as it rotates with shaft and armature core.

Usually, wire made up of copper is used for armature winding. The wounded wire is placed over the slots of the armature core and forms armature winding.

When the armature winding rotates in the flux generated by the field winding, e.m.f. is induced in the conductors or wire of the armature winding according to the principle of Faraday's law of Electromagnetic Induction.

Commutator :

The commutator is also one of the essential parts of a dc generator. Because without a commutator a dc generator would become an ac generator. The function of a commutator is that as to convert a.c. generated supply in the armature winding into d.c. supply and send it to the load circuit.

It is cylindrical in shape with high conductivity copper segments separated by an insulation material (generally mica) is placed over it. Each conductor of an armature winding is connected to each segment of the commutator. The commutator is positioned in between two stationary brushes and rotates with the shaft and armature winding.

Shaft :

The shaft of a dc generator gives mechanical support to the armature winding and commutator to rotate between magnetic flux produced by the magnetic poles. It is of iron material and supported between bearings. Its main function is to transfer mechanical rotation given to the generator to the armature winding and to make the armature rotate.